In a time where consumers and businesses alike are working to cut back on single-use plastics, it’s easy to see an alternative material and believe that it is the more eco-friendly option. However, this is not always the case.

One suggested alternative, aluminium cans, may mean less ocean waste than improperly discarded plastics, but the carbon emissions of producing one aluminium can is approximately twice that produced by manufacturing a plastic water bottle. According to the University of New South Wales, the production of new aluminium represented 6.5 per cent of Australia’s greenhouse gas emissions in 2020.

If plastic is recycled, it’s the best and cleanest solution for water bottles.

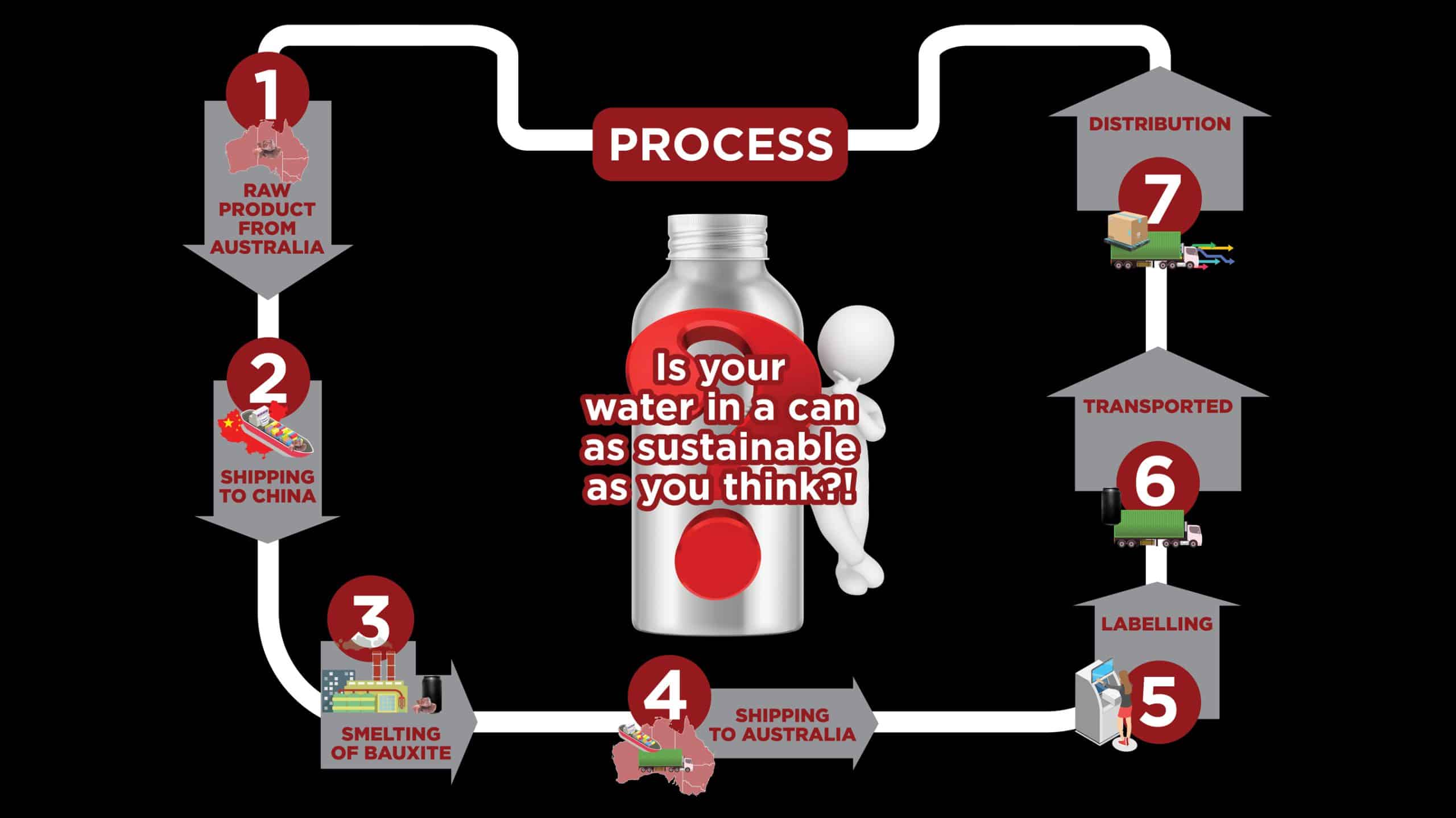

The production of aluminium cans involves several processes that contribute to greenhouse gas emissions. Here’s a breakdown of the key emissions associated with the production of aluminium cans:

Bauxite Mining

Firstly, bauxite is mined from the northern tip of Australia. Both mining and refining processes for bauxite are energy-intensive and can contribute to carbon dioxide (CO2) emissions.

Shipping to China for smelting

The bauxite is then loaded onto cargo ships destined for China, where it is smelted, meaning heat is applied along with a chemical reducing agent in order to extract a desired base metal product – in this case, aluminium. This process involves a significant amount of electricity and is a major source of greenhouse gas emissions. The primary emission is from the consumption of carbon anodes in the electrolytic cells, which releases carbon dioxide. The aluminium is then made into a can before being shipped back to Australia.

Trucking in Australia

On arrival in Sydney, the aluminium cans are transported via truck to a warehouse where labels are produced and applied to cans.

Transport to the Sunshine Coast

Once labelled, the cans are freighted by road to the Sunshine Coast to be filled. When the cans have been printed with customer labels and filled with water, they are palletised and ready for distribution around Australia. The use of fossil fuels in trucks, ships, and other transportation modes releases CO2 and other pollutants.

Recycling aluminium requires much less energy than primary production, making it a more sustainable option. However, aluminium cans are not the eco-friendly plastic water bottle alternative they are purported to be.

We believe in being responsible for the region you live in, and we strive to minimise the environmental impacts of running our business in the beautiful Far North.

Another part of our green initiative is a specialised blow-moulding machine enabling us to produce our own bottles on-site and avoid interstate road transport to Far North Queensland.

Our drink bottles are made from pre-forms the size of test tubes. This small size enables us to get one pallet sent on a truck from Brisbane, replacing 22 pallet spaces of ready-made water bottles. The blow-moulding machine has been a great investment and a huge reduction in road travel emissions.

As for road travel emissions locally, our hybrid delivery truck continues to reduce the company’s environmental footprint, and we aim to eventually have a fully electric truck.

Although aluminium cans can appear to be more eco-friendly than plastic, there is more to it than the final product. In fact, a great deal of the sustainability of a product is to do with its production process.

Remember, we all have a part to play in protecting the reef and the air from pollution. We partner with Containers for Change to encourage consumers to think of the environment while earning some pocket money to keep or donate on to local charities and community groups.

Quick links

MON – FRI: 8:00am – 4:30pm

P (07) 4033 2454 E sales@cairnsnaturalspringwater.com.au

Block 1, 52-64 Links Drive, Woree, 4868 QLD

Our Opening Hours

MON – FRI: 8:00am – 4:30pm

Copyright © 2025 Cairns Natural Spring Water | Developed by Adllins Media